Water Treatment Services

Water is becoming increasingly scarce, and as a result, the water treatment market has seen rapid growth since the late 1990s. Those working in the sector now encounter increasingly complex challenges, from guaranteeing high water quality to meeting ever-more closely monitored regulations.

From the treatment of water for human consumption to the water used in daily lives, Alokozia Ltd., continues to enjoy a strong reputation as a reliable and consistent partner delivering solutions tailored to meet any given need. Exploiting our market experience, we design, develop, test, and manufacture solutions and systems that deliver precision and consistency, ease of use, installation, and operational efficiency.

Challenging water treatment applications, where the metering of toxic, corrosive, and other hazardous chemicals is commonplace, demand dosing solutions that are robust, reliable, and accurate while offering exceptional repeatability. That’s where Alokozia’s range of motor-driven diaphragm and plunger piston dosing pumps comes in.

Offering flow rates as high as 2,065 l/h, pressure ratings up to 200 bar, and watertight construction, our motor-driven pumps are adaptable and safe for a comprehensive range of metering processes, including agricultural, food and beverage, potable, and wastewater treatment.

To ensure these pumps operate with maximum efficiency, precision, and chemical compatibility in tough water-treatment environments, they’re built with only the highest-quality components, including PVC and PVDF heads, PTFE diaphragms, and 316L stainless-steel pistons

For most common water treatment, Alokozia Ltd. can provide high-quality, up to the mark and versatile chlorine dosing pumps for water treatment. The available dosing pumps are ranged from low capacity to medium and high capacity metering pumps. These include Tekba (Solenoid-driven), Kosmo (Motor-driven), Spring S2 (Motor-drive), and Kronos 50 (Peristaltic-driven) series pumps and further details can be found as follows:

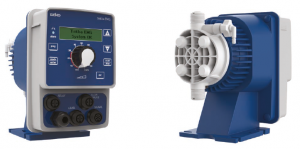

1. Tekba-R

Tekla-R is a range of digital solenoid-driven dosing pumps with mechanical stroke-length regulation. It represents a state-of-the-art solution for its reliability, dosing precision, and ease of use and has been designed in response to positive customer feedback on the Tekna Series. The Tekba-R Series offers a modern and reliable product, a reference point in the base-mounted dosing pump sector.

- Flow rate range: 2.5 – 110 l/h, up to 20 bar

- Wetted parts: PVDF, PTFE, FFKM, EPDM, FKM-B, and Ceramic

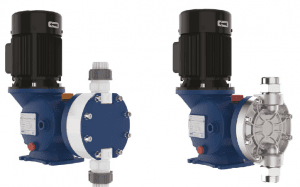

2. Kosmo MM1

- < Flow rate range: 9 – 530 l/h, up to 12 bar

- < Wetted parts: SS316L, PVDF, PTFE, FPM, EPDM, and ceramic

3. Spring PS2

- Flow rate range: 40 – 1,000 l/h, up to 20 bar

- Wetted parts: SS316L, PVC, PTFE, FPM, EPDM, and ceramic

The PS2 series of piston dosing pumps offer multiple combinations of pump head, motor power, and stroke lengths that enable it to be arranged in several hydraulic configurations, making the range suitable for multiple applications.

PS2 pumps have a spring-return mechanism in robust aluminum housing, and each model can be configured with two different stroke rates. To adjust the flow rate of the pump, the stroke length can be adjusted manually or even automatically, by using the AKTUA Kit controlled by a 4-20mA signal or by a pulse emitting water meter.

PS2 pumps are available with a 3-phase or a single-phase electric motor, both with IP55 protection.

4. Kronos 50

As with the other Kronos pumps, Kronos 50 is equipped with a stepper motor that provides infinitely adjustable (0.1- 100%) and silent dosing. Its advanced technology and materials mean the various models can reach flow rates of up to 15 l/h (at 0.1 bar) and can dose at back pressures up to 4 bar with a special HP-San tube.

- Flow rate range: 2 – 15 l/h, up to 4 bar

- Tube: Santoprene – SekoExtra – SekoMed – Sekofort – HP-San

The digital programming of parameters via keyboard and display ensures a fast setup and final check on the programming data. The easy and intuitive menu enables a simple setting of the various options without the risk of forgetting anything. The internal menu also allows users to check statistics on the life of the tube and the operating life of the pump.